जीआई केबल ट्रे

उत्पाद विवरण:

- कंडक्टर सामग्री ,

- सतह की फ़िनिश , ,

- प्रॉडक्ट टाइप

- रंग

- केबल का प्रकार GI CABLE TRAY

- मटेरियल GI ,MS,ALLUMINIUM CABLE TRAY

- अधिक देखने के लिए क्लिक करें

जीआई केबल ट्रे मूल्य और मात्रा

- मीटर

- मीटर

- 100

जीआई केबल ट्रे उत्पाद की विशेषताएं

- GI ,MS,ALLUMINIUM CABLE TRAY

- GI CABLE TRAY

जीआई केबल ट्रे व्यापार सूचना

- Delhi

- ,

- 5000 प्रति महीने

- 10 दिन

- No

- PLASTIK WRAPPING

- MSME ISO

उत्पाद वर्णन

उत्पाद विवरण

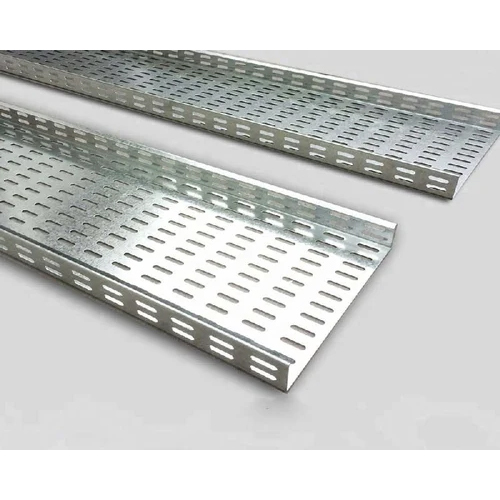

GI Cable Tray Manufacturers Product & Company Description

We are leading GI (Galvanized Iron) Cable Tray Manufacturers, specializing in the design, production, and supply of high-quality cable management systems for industrial, commercial, and infrastructure projects. Our GI cable trays are manufactured using premium-grade galvanized steel, offering superior corrosion resistance, durability, and load-bearing capacity.

Our product range includes:

-

Perforated GI Cable Trays

-

Ladder Type GI Cable Trays

-

Raceways and Trunking Systems

-

Accessories: Bends, Tees, Reducers, and Covers

Key Features:

-

Made from hot-dip galvanized steel as per IS & IEC standards

-

Rust and corrosion-resistant surface finish

-

Available in various sizes, thicknesses, and finishes

-

Easy to install, maintain, and expand

-

Suitable for indoor and outdoor applications

Applications:

-

Electrical wiring distribution in factories and plants

-

Data center and IT infrastructure cabling

-

Commercial buildings and malls

-

Power plants and substations

-

Railways, airports, and metro systems

Why Choose Us?

-

State-of-the-art manufacturing facility

-

Customization available as per project needs

-

Timely delivery and competitive pricing

-

ISO-certified quality systems

-

Technical support and after-sales service

Whether you need standard or customized GI cable tray solutions, we are your trusted partner for reliable and efficient cable management.

उत्पाद विवरण

Cable Tray Coating -Pre-Galvanized

Materials - Gi

Size -50 to 600mm

Usage/Application -electric

Country of Origin -Made in India

Thickness - 2.5 mm

Tray Type - Perforated Cable Tray

Robust Material Choices

We offer cable trays in GI, MS, Aluminium, and Steel, providing flexibility to meet various structural or environmental demands. Whether you require lightweight aluminum, the strength of steel, or cost-efficient GI, our products cater to diverse projects while ensuring lasting performance.

Versatile Surface Finishes

Our cable trays are finished using HDG, powder coating, or GI galvanizing, enhancing resistance to corrosion and environmental exposure. These finishes extend tray lifespan and maintain their appearance, even in demanding industrial or outdoor environments.

FAQs of GI Cable Tray:

Q: How are GI cable trays installed and where are they typically used?

A: GI cable trays are installed along walls or ceilings to support and neatly organize power and data cables. They are commonly seen in industrial plants, commercial buildings, data centers, and infrastructure projects across India.Q: What materials are available for the cable trays, and how do I choose the right one?

A: We offer cable trays in GI (Galvanized Iron), MS (Mild Steel), Aluminium, and Steel. Your selection depends on load requirements, environmental conditions, and budget. Aluminium is lightweight, GI and GI Galvanized offer cost-effective corrosion resistance, while steel provides maximum strength.Q: What surface finish options are provided for these cable trays?

A: Cable trays come finished as Hot Dip Galvanized (HDG), Powder Coated, or GI Galvanized. These finishes protect the trays from rust, corrosion, and mechanical wear, allowing you to select according to the specific environment.Q: When should powder coated or HDG cable trays be used?

A: Powder coated trays are best for indoor applications where color coding or aesthetic integration is important. HDG trays excel in outdoor or humid settings due to superior corrosion resistance afforded by the thick zinc coating.Q: What benefits do these cable trays offer in cable management?

A: Our cable trays provide organized cable routing, improved airflow to prevent overheating, easy access for future maintenance, and enhanced safety by minimizing cable clutter. The various finishes and materials guarantee longevity and dependability in diverse environments.Q: Where do you manufacture and supply these cable trays?

A: We are based in India, serving clients nationwide as both a manufacturer and supplier, ensuring timely delivery and support for projects across various sectors.

Price: Â

- 50

- 100

- 200

- 250

- 500

- 1000+

जांच भेजें

जांच भेजें एसएमएस भेजें

एसएमएस भेजें